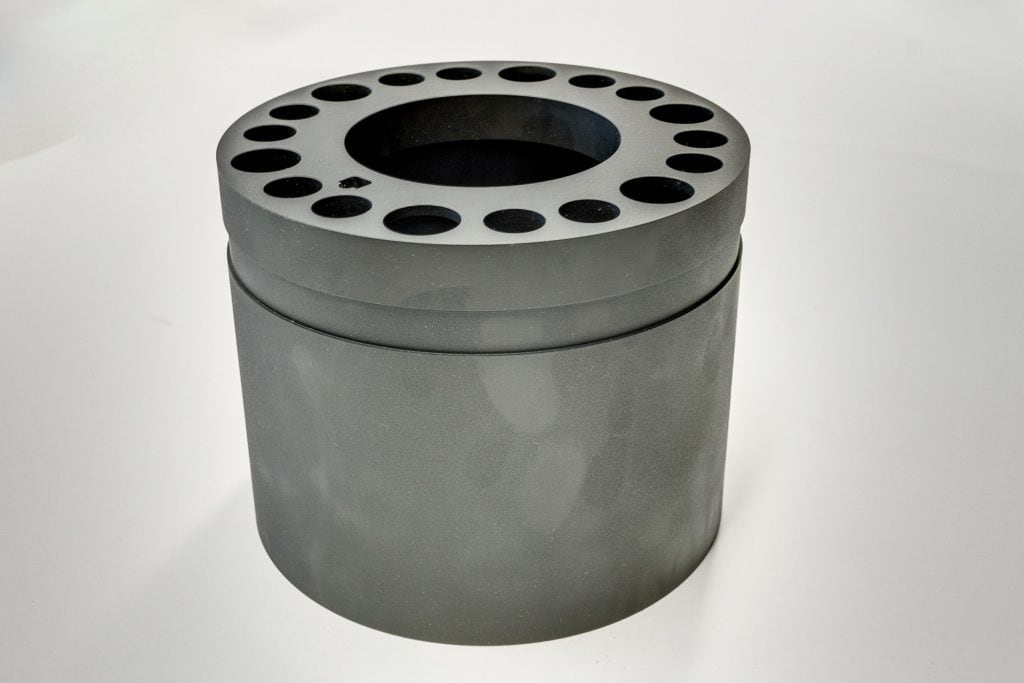

Mallory Industries, Inc is dedicated to possessing the most advanced technology that will help us meet the expanding needs of diverse industries. Therefore, we possess two wire EDM machines that can produce intricate details from hard to process metals, such as tool steels, alloy steels, and all grades of stainless steels and aluminums – meeting an extremely tight, (+/-) 0.0002 of an inch precision tolerance.

Our wire EDM machines are equipped with an 18 X 18 X 18 inch work envelope and a 1500 pound bed capacity. With our advanced wire EDM services, we have been able to manufacture complex medical components that have been used in life-saving devices. We have also produced numerous aircraft parts and industrial equipment components.

Our advanced wire electrical discharge machining (EDM) services have allowed us to manufacture a wide variety of complex machined parts for multiple industries. We invite you to contact Mallory Industries, Inc today to learn more about our wire EDM operations or any of our other superior machining services.

Capabilities