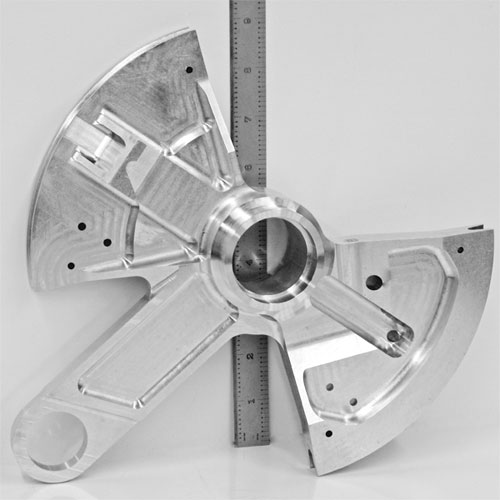

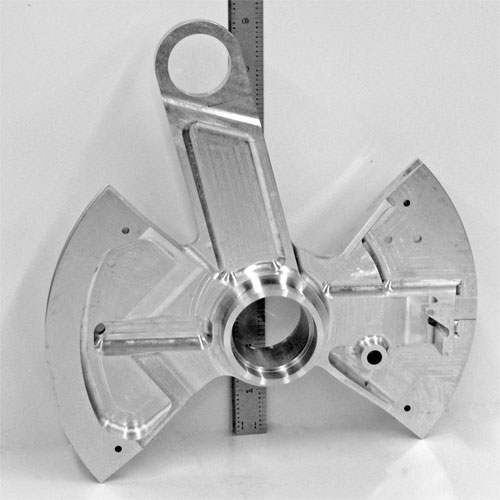

The component pictured was manufactured by Mallory Industries, Inc to be used within a helicopter application. Using our CNC turning and 3-axis CNC high speed milling machinery, which meets ultra-tight tolerances as close as ± .00025″, we produced this part from 7075-T7351 aluminum material to measure precisely 10.75″ x 9.68″ in length and width, with a thickness of 2.5″. The part also possessed a smooth, 32 RMS surface finish.

The finished helicopter component featured bearing bores and journals, a hole true position tolerance of .001″, and 3-D milling capabilities. Fulfilling our customer’s specifications, we produced 50 of these parts for the aerospace industry, satisfying all expectations for quality.